4.

Track 1: Regarding the direction of CAISO’s UCAP proposal, please share your organization’s feedback on key elements discussed at the workshop such as implementation through CAISO NQC process, assessment hours, and interaction with LRA QC methodologies.

CAISO presented its initial leaning to develop UCAP values based on resource-specific Effective Forced Outage Rate in-demand (EFORd) calculations, where it determines that a specific resource is in-demand during “supply cushion hours.” It would apply its UCAP methodology to any resource QC that was not determined based on a probabilistic or performance-based Local Regulatory Authority QC methodology.

CESA supports the development of resource-specific EFORd values. However, there are several issues with CAISO’s proposal that require further consideration.

CESA Opposes the Use of Supply Cushion Hours to Define When Specific Resources Are In-Demand Under the UCAP Methodology

The CAISO proposes to deem that all resources are de facto in-demand during “supply cushion hours.” The supply cushion hours represent how much shown RA remains after serving net load, meeting contingency reserves, and accounting for all outages, then selecting the 20% most constrained hours within each season. This approach is meant to identify the hours in which a resource would have been in-demand.

The supply cushion hour approach is a radical departure from industry practice of using either system-wide high load (or net load) hours or, more accurately, individual unit economics. Although industry practice has varied, the approach that aligns most closely with resource-specific performance considers to the greatest extent possible factors influencing the demand for individual resources.

CESA remains committed to developing a resource-specific UCAP methodology that establishes accurate and comparable UCAP values. To achieve accurate and comparable UCAP values, the identification of the in-demand hours must follow a resource-specific methodology that considers unit economics

The supply cushion hour approach is not a resource-specific methodology. The supply cushion hours are determined at a system-wide level and attempt to identify when RA resources would be in-demand. However, the calculation depends on several factors that are not related to whether an individual resource would be in demand. First, the calculation is based on the specific set of resources that LSEs include on their RA Plans for a given month and the specific make-up of those portfolios change from month to month. Second, the calculation subtracts the impact of planned outages on the shown resources. This is problematic because the supply cushion would depend on the particular resources LSEs have decided to include on their plans, at no fault of the individual suppliers, and there are major maintenance outages that do not occur every year that would skew the selection of the in-demand hours from year to year. Third, the supply cushion hour approach does not identify if individual resources were actually in-demand, as the chosen hours may be the same hours in which there was plenty of available import supply for CAISO to reliably operate the grid or the same hours in which resources in local areas would have been constrained due abundant low-cost generation.

The supply cushion hour approach fails to recognize unit economics. Each resource on the system is subject to a different economic reality, given individual resource operating and opportunity costs, as well as local constraints. If CAISO would not have economically dispatched an RA resource in a given hour because other cheaper resources were available behind a local constraint, the resource should not be arbitrarily penalized through the UCAP methodology. Likewise, if imports were cheaper and readily available in a given hour such that an RA resource would not have been economically dispatched, then that RA resource was not actually in-demand.

The clearest indication that the supply cushion hour approach is flawed is the hours that CAISO identified for 2022-2023. This data shows many days on which all 24 hours would be identified as in-demand as well as many more days in which 1 a.m. through 5 a.m. were identified as in-demand. The CAISO has not made a clear demonstration that the supply cushion hours represent the hours in which individual resources would be in demand or the hours in which there is a reliability need for capacity.

CESA proposes to determine resource-specific in-demand hours based on unit economics

EFORd values measure the probability that a generating unit will not be available due to forced outages or forced deratings on its Pmax, forced derates on its Maximum Continuous Energy Limit, forced rerates on its Minimum Continuous Energy Limit, and forced rerates on its Pmin when there is demand on the unit to generate. Measuring historical performance, EFORd is calculated as the percentage of total demand time that a unit was unavailable due to forced outages. It is important to only assess outages at times when the resource was or would be dispatched by the CAISO, as an outage in the middle of the night is typically of no consequence to system reliability.

Using the EFORd performance index necessarily requires a definition of when the resource is “in demand.” Further, the “in demand” intervals must be clearly defined for two states: while the resource is in service and while the resource is on forced outage.

CESA proposes in-service in-demand hours to be all intervals where an energy storage resource receives a dispatch. This is obvious, because if the resource received an economic dispatch from CAISO, it was among the most cost-effective ways to meet demand at the time. Typically, the resource’s PNode price during these intervals will be greater than or equal to its bid price.

CESA proposes that in-demand hours while the resource is on forced outage be determined using the PNode prices, the resources’ DEB price, and are aligned with how the resource would typically be operated over the course of the day given its normal operating limitations. In general, the forced outage hours in-demand would be the highest priced intervals of the day where the resource PNode price is greater than or equal to its DEB price and the resource is on outage, plus the prior intervals that would have been required to charge the resource to meet awards. CESA discusses this further in the next section.

In-demand hours must be limited to only those hours that a storage resource would be expected to operate aligned with its normal operating limitations, such as its maximum continuous stored energy limit and the required hours to fully charge the resource accounting for round-trip efficiency losses

EFORd values measure the probability that a generating unit will not be available due to forced outages or forced deratings on its Pmax, forced derates on its Maximum Continuous Energy Limit, forced rerates on its Minimum Continuous Energy Limit, and forced rerates on its Pmin when there is demand on the unit to generate. Measuring historical performance, EFORd is calculated as the percentage of total demand time that a unit was unavailable due to forced outages. It is important to only assess outages at times when the resource was or would be dispatched by the CAISO, as an outage in the middle of the night is typically of no consequence to system reliability.

Using the EFORd performance index necessarily requires a definition of when the resource is “in demand.” Further, the “in demand” intervals must be clearly defined for two states: while the resource is in service and while the resource is on forced outage. Determining if a resource was in demand during a forced outage/derate is a two-part process. First, identify the hours in which the resource would have been discharged using hourly PNode prices and Default Energy Bid (“DEB”) prices (i.e. the Discharge Forced Outage Hours in demand, or “Discharge FOHd”). Second, determine the hours the resource would have needed to have charged to support the presumed discharge (i.e. the Charging Forced Outage Hours in demand, or “Charging FOHd”), if any.

- In-Service Hours in demand (“Service Hours”). All intervals where the resource is in service and receives a dispatch award.

- Discharge FOHd. Evaluate all intervals where the resource is on forced outage or derate and the Pricing Node (“PNode”) price is greater than or equal to the resource Default Energy Bid (“DEB”) price. If the number of evaluation intervals in a single day exceeds the resource Maximum Continuous Energy Limit divided by the resource Pmax (Number of Maximum Discharge Intervals), limit the evaluated intervals to those where PNode price is greater than or equal to DEB price and PNode price is in the set of intervals with the highest PNode prices on the same day corresponding to the Number of Maximum Discharge Intervals.

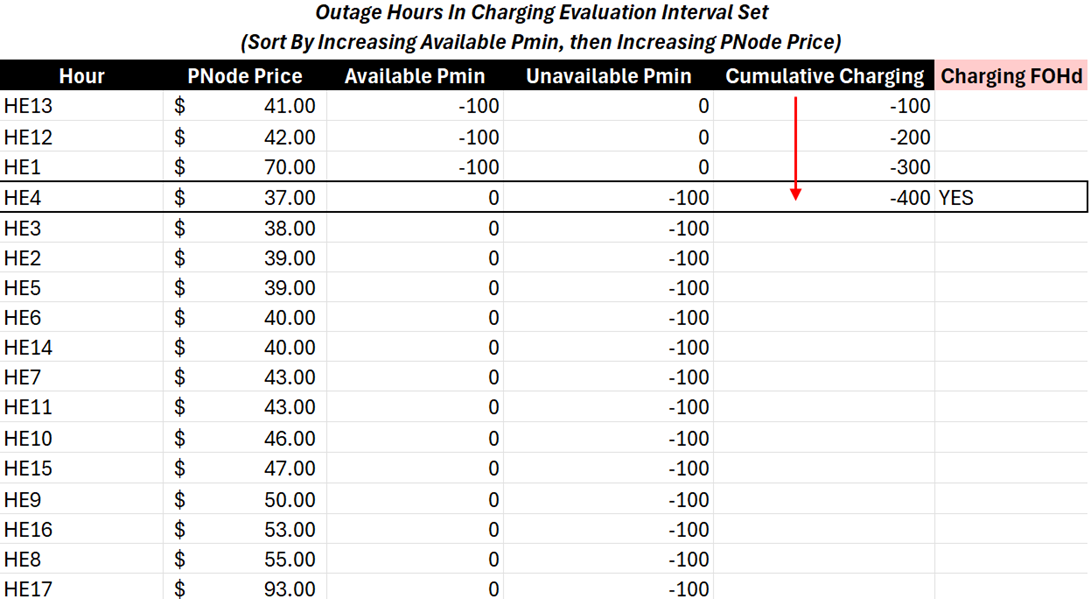

- Charging FOHd. Evaluate all intervals in the same day prior to Discharge FOHd (Charging Evaluation Interval Set) to determine if there was enough available charging capacity to support the Discharge FOHd. Calculate the Charging Need as the sum of the Unavailable Pmax during Discharge FOHd divided by the resource round-trip efficiency. Calculate the Available Charging Capacity as the sum of the Available Pmin in the Charging Evaluation Interval Set. Calculate the Forced Charging Need as the minimum between zero and the Charging Need minus the Available Charging Capacity. The Charging FOHd is the set of intervals the resource is on Forced Outage/Derate in the Charging Evaluation Interval Set where PNode Prices are the lowest, limited to the number of intervals required to meet the Forced Charging Need.

Regarding the Discharge/Charging FOHd determination, consider a resource with a 100 MW Pmax, -100 MW Pmin, a 400 MWh Maximum Continuous Energy Limit, and a 75% round-trip efficiency. Assume this resource is on two forced outages in a single day, one outage from Hour Ending (“HE”) 2 through HE11, and another outage from HE14 through HE21.

The first step is to determine the Discharge FOHd by examining the hourly PNode Prices and DEB prices. Given that this is a 4-hour duration resource, find the four highest priced hours of the day where the PNode price is greater than or equal to the DEB price and the resource is on forced outage. The figure below shows that HE18 through HE20 are Discharge FOHd.

Figure 1: First Determine the Discharge FOHd

The second step is to determine the amount of charging capability that would have been needed for the resource to produce at Pmax during the Discharge FOHd (Forced Charging Need). Sum the Unavailable Pmax in each Discharge FOHd and divide by the resource round-trip efficiency. In this example, the resource was unable to produce 300 MWh from HE18 through HE20, requiring 400 MWh of Forced Charging Need earlier in the day (300 MWh divided by 0.75 is 400 MWh).

The third step is to determine how many, if any, forced outage intervals the resource would have needed to have been available prior to Discharge FOHd on this day to achieve 400 MWh of charging at full Pmin. Take the set of hours from HE1 through HE17 (all hours prior to Discharge FOHd, or “Charging Evaluation Interval Set”) and sort by increasing Available Pmin then by increasing PNode price. Starting at the top of the sorted set (presumably intervals with Available Pmin), iterate until Available Pmin plus Unavailable Pmin equals 400 MWh. This sorting allows intervals in which the resource has available charging capability to be used before determining that the resource would have had to have charged while on forced outage. The forced outage hours needed to achieve the full 400 MWh of Forced Charging Need are the Charging FOHd.

Figure 2: Identify the forced outage intervals prior to Discharge FOHd that would have been needed to support the Discharge FOHd

In this example, HE4 and HE18-HE20 are considered in-demand for purposes of calculating the resource EFORd value.

CESA Opposes the Selection of Specific Outage Nature-Of-Work Codes That Would Be Considered a UCAP Forced Outage, Because the CAISO Has Not Provided an Unambiguous UCAP Forced Outage Definition

The CAISO proposes to identify specific outage nature-of-work codes that its Outage Management System (OMS) has categorized as “Forced” outages. CESA would find any stakeholder’s identification of an outage code as one that “should be” included as a UCAP forced outage highly suspect, as CAISO has not yet clearly defined a UCAP Forced Outage.

Absent a clear definition of a forced outage for UCAP purposes, it would be problematic to identify which outage codes should be used in calculating a UCAP value. It is unclear what standard is being applied to select the appropriate outages, and CAISO has not established a process to allow impacted entities to provide input as UCAP values are being developed. In fact, several of the “Forced” outages in the CAISO’s OMS would not fit the NERC GADS forced outage definition. The forced outage definition continues to be a moving target and the longer it remains undefined, the more questionable any outage code categorization will be.

CESA proposes unambiguous forced outage definitions (for UCAP purposes), based on the North American Electric Reliability Corporation (NERC) GADS definitions, as well as an established process for suppliers to provide necessary input to ensure the accuracy of the UCAP calculation. CESA expects that this definition will not initially map directly to an existing outage type or nature-of-work code, so CAISO must allow suppliers the opportunity to review and verify the CAISO’s initial outage classification.

CESA proposes the following UCAP Forced Outage definition which combine NERC GADS Event Types U1, U2, U3, D1, D2, and D3 and ensures the definitions are appropriately focused on equipment failures:

Forced Outage/Derate (Immediate). This is an outage that requires immediate removal of a unit from service, derating, or another outage state due to equipment failure or risk of imminent equipment failure. This type of outage usually results from automatic control system trips or operator initiated manual trip of the unit in response to unit alarms but can also occur while the unit is offline.

Forced Outage (Delayed). This is an outage that does not require immediate removal of a unit from the in-service state or derating due to equipment failure or risk of imminent equipment failure, instead requiring removal or derating within six hours. This type of outage can only occur while the unit is in service.

Forced Outage (Postponed). This is an outage that can be postponed beyond six hours but requires that a unit be removed from the in-service state or derated due to equipment failure or risk of imminent equipment failure before the end of the next weekend (Sunday at 2400 or before Sunday turns into Monday). This type of outage can only occur while the unit is in service.

CESA Proposes a Forced Outage Classification Verification Process

Recognizing that a clear UCAP forced outage definition may not necessarily align within OMS’ existing outage codes, CESA proposes suppliers be given the opportunity to review and verify the CAISO’s initial outage classification. During this process, suppliers will provide corrections to each outage classification, along with the reason, and attest that the provided corrections align the outage classifications with the forced outage/derate definition.

The CAISO should endeavor to transparently apply as many appropriate type, timing, and natures-of-work screens as needed to develop a draft list of outages and whether each outage meets the forced outage definition or not. However, CESA expects the outage classifications based on the data available from OMS will not initially directly align with the forced outage definition. Suppliers will then be given the opportunity to verify the draft classification. Suppliers will submit the outage data list back to CAISO including its re-classifications, the reason the outage re-classifications are aligned with the forced outage definition, and a senior official attestation to the accuracy of the re-classifications.

This Forced Outage Classification Verification Process is meant to bridge the gap between the clear definition of a forced outage that should impact a resource’s UCAP value and the technological limitations with the source outage data. If the CAISO OMS is updated to incorporate a “UCAP forced outage” flag that meets the clear definition of a forced outage for UCAP purposes, this process may be retired after suppliers have been given an opportunity to review and verify the classification of outages prior to the existence of such a flag.